Technical Guide: Understanding LED Sheets –

Specs, Layers & How They Work

Specs, Layers & How They Work

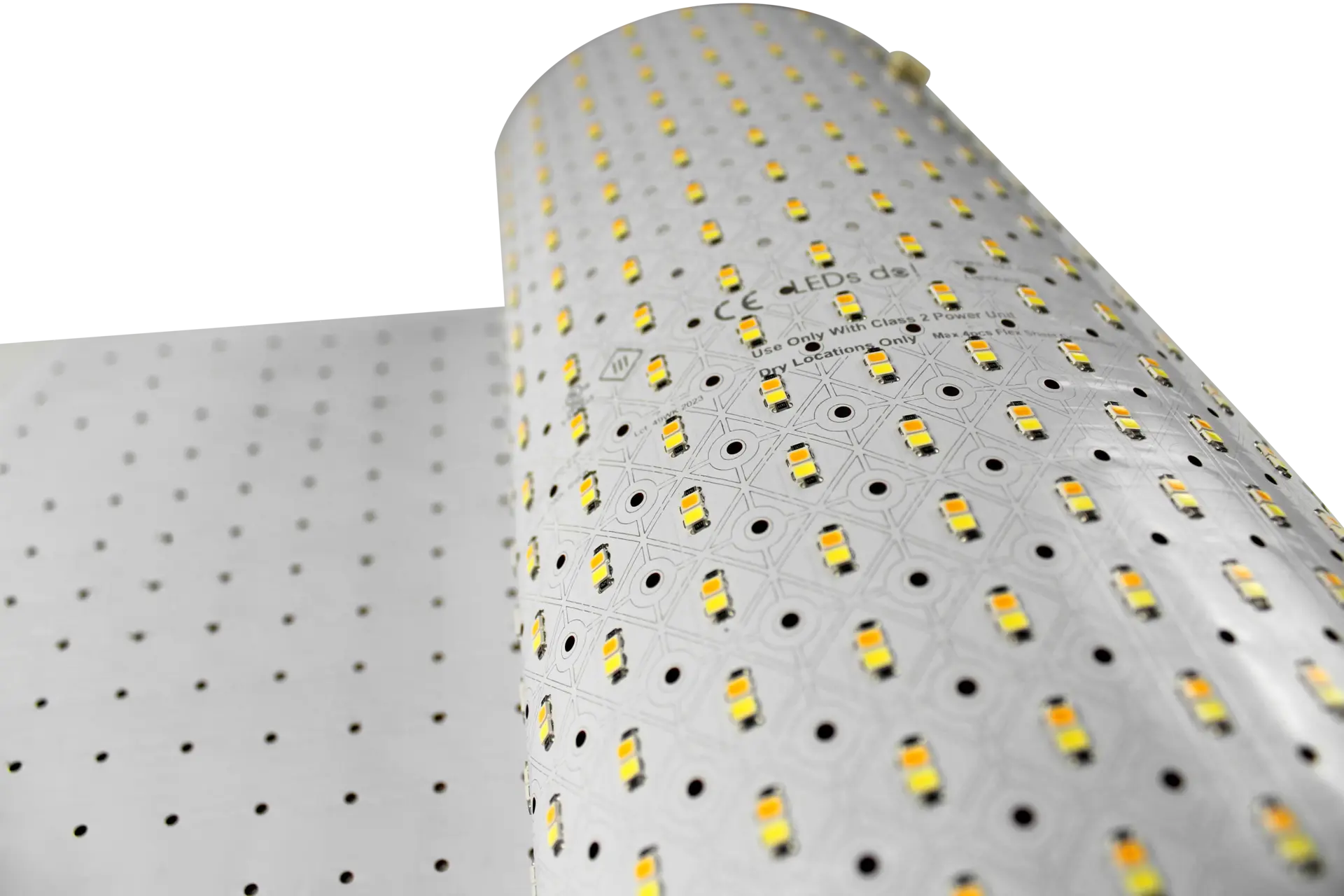

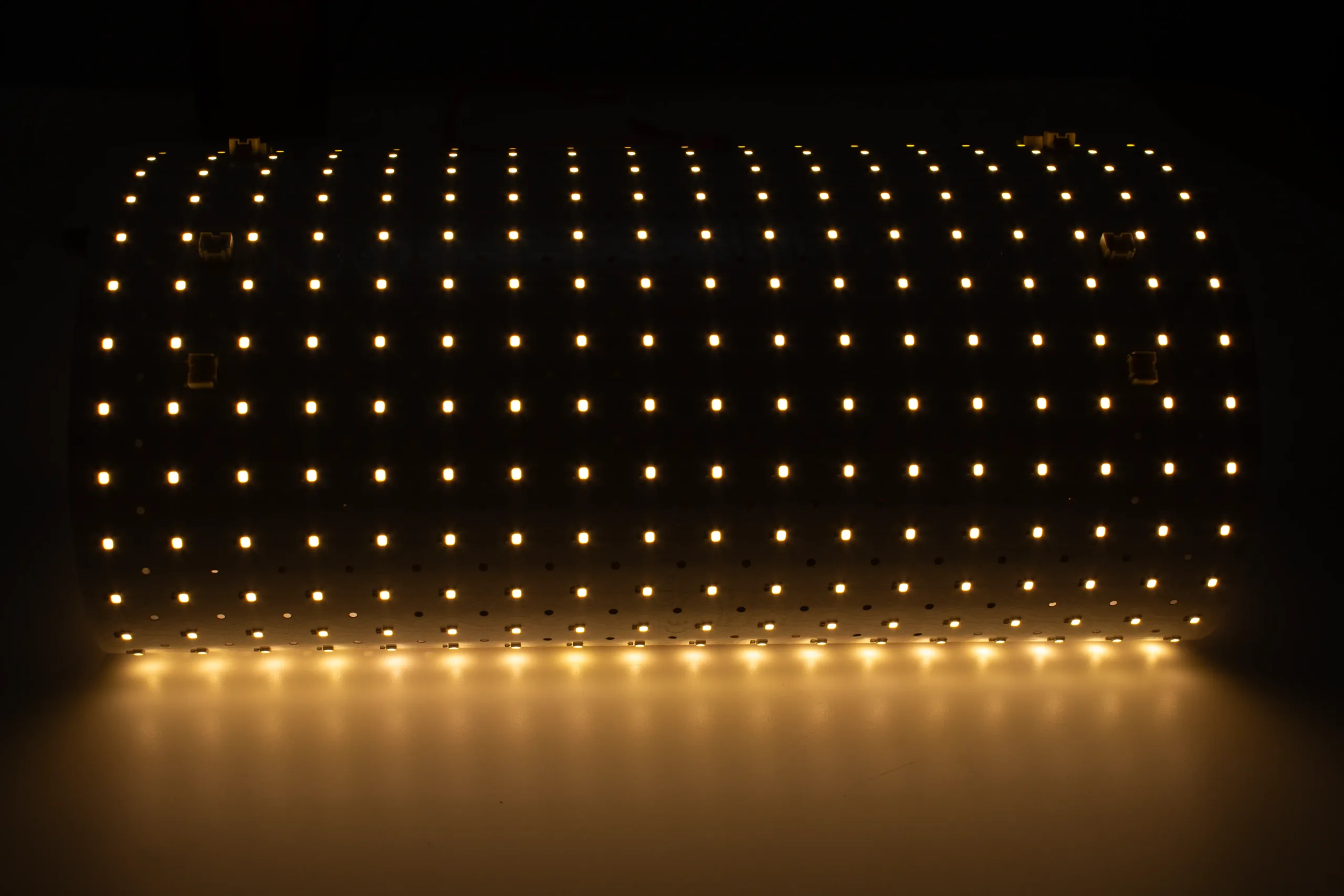

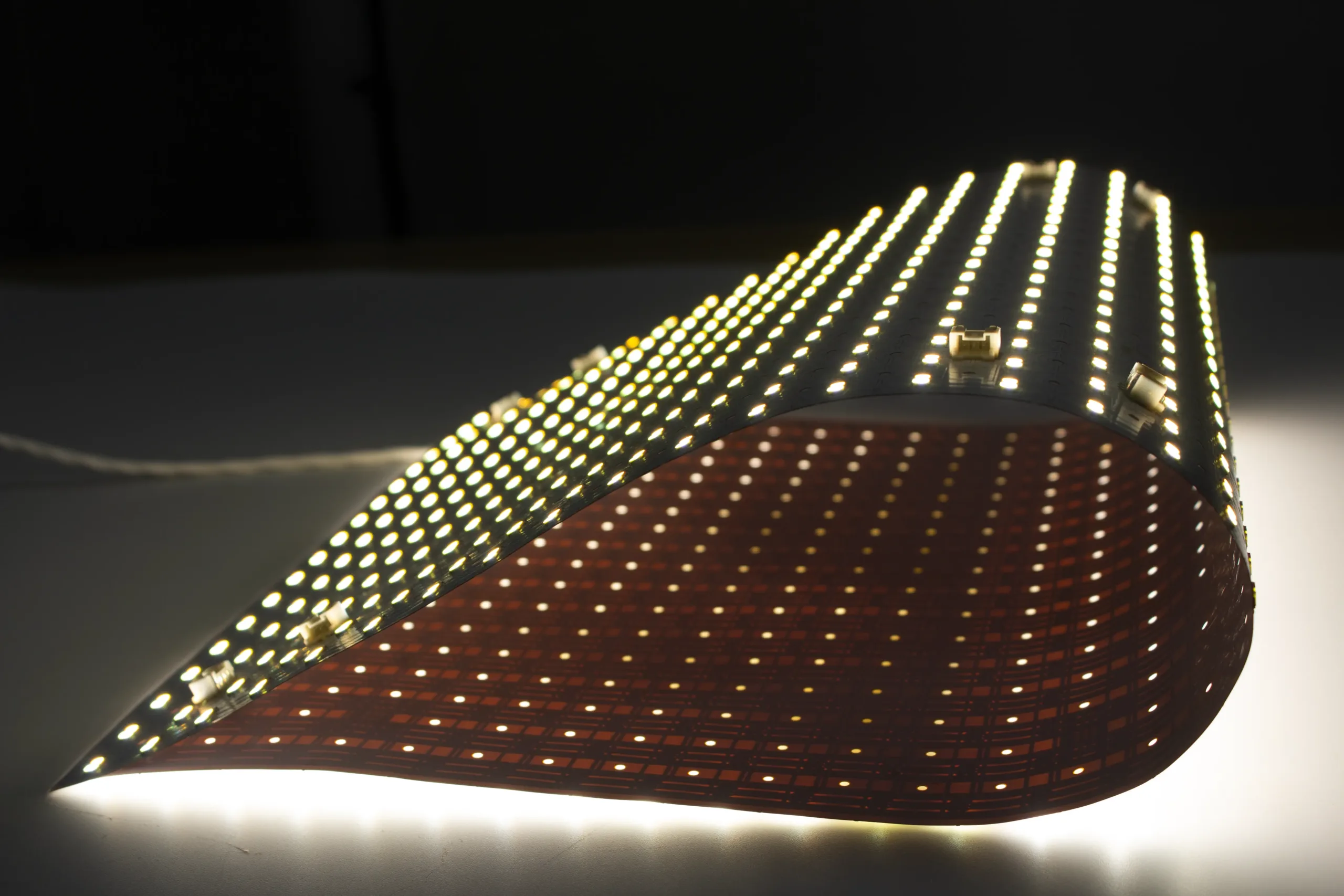

LED sheets (also called flexible LED sheets or cuttable LED sheets) are ultra-thin, modular lighting solutions that provide uniform illumination without hot spots. This guide covers their construction, performance, and technical specifications, so you can select the right sheet for signage backlighting, architectural lighting, retail displays, or custom installations.

What Are LED Sheets and How Are They Made?

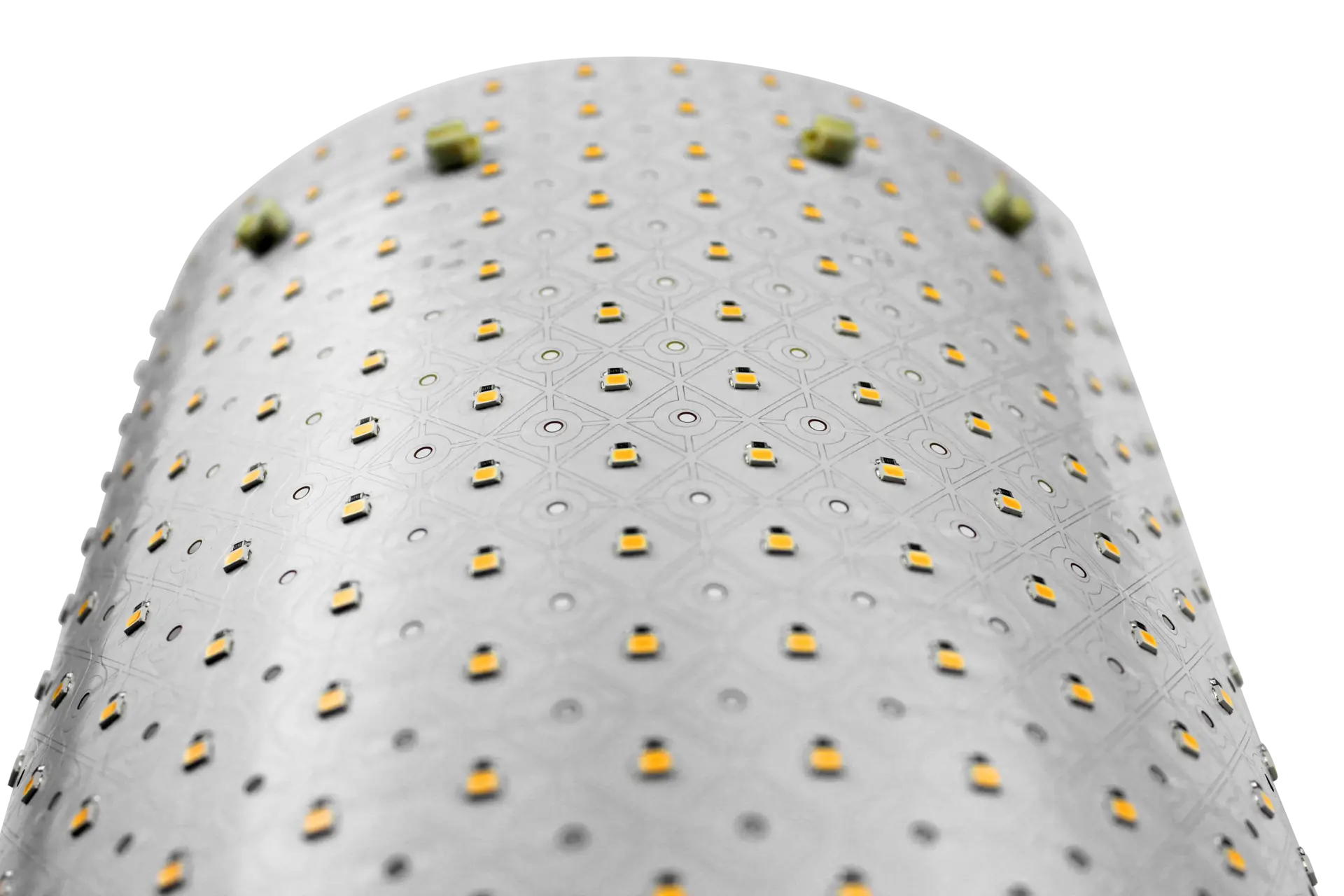

A typical LED sheet contains:

- Substrate layer: polycarbonate, acrylic, or PCB for stability.

- LED chips: surface-mounted in a grid pattern.

- Circuit traces: copper or conductive ink pathways.

- Diffusion layer: optical film or laser-etched acrylic for even light spread.

- Optional adhesive backing for simple mounting.

Standard Sizes & Thickness Options

- Sizes: 12″ × 12″, 24″ × 24″, 48″ × 96″ (or custom).

- Thickness: 1mm – 6mm depending on substrate and LED density.

Light Output & Efficiency (Lumens per Watt)

- Low density: ~500 lumens/ft²

- High density: ~2000 lumens/ft²

- Typical efficiency: 80–140 lm/W

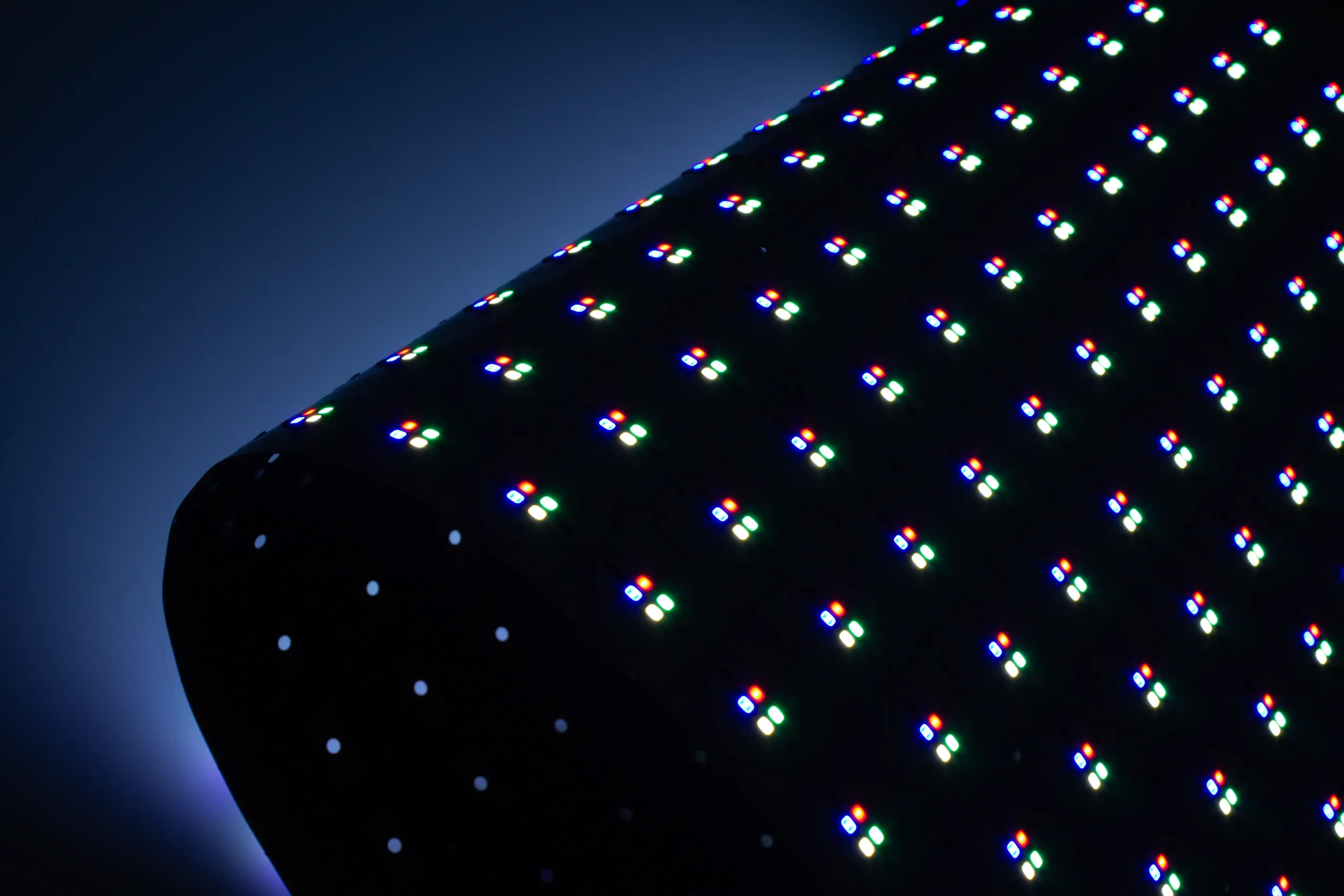

LED Types & Color Temperatures

- SMD 2835: efficient, compact, used for general lighting.

- SMD 5050: brighter, supports RGB/RGBW.

- SMD 3528: decorative, lower brightness.

- Color temps: warm white (2700K), neutral, cool white (6500K+), and RGBW options.

Power Standards & Voltage Options

- 12V DC: small installs (under-cabinet, signage).

- 24V DC: larger sheets, reduced voltage drop.

- 36–48V DC: industrial projects.

Power Consumption & Current Ratings

- Draw: 3W – 20W per ft²

- Current: varies by density (measured in mA or A).

Light Distribution (Edge-Lit vs Direct-Lit)

- Edge-Lit sheets: LEDs placed along edges; diffusion pattern spreads light.

- Direct-Lit sheets: LEDs across surface; higher brightness, no shadows.

Dimmability & Control Systems

Most flexible LED sheets are dimmable and support:

- PWM dimmers (flicker-free)

- Smart controllers (WiFi/Bluetooth)

- DMX/DALI systems (professional projects)

Heat Dissipation & Lifespan

- Low heat output thanks to LED efficiency.

- Some include thermal control layers or heat sinks.

- Lifespan: 50,000 – 100,000 hours depending on conditions.

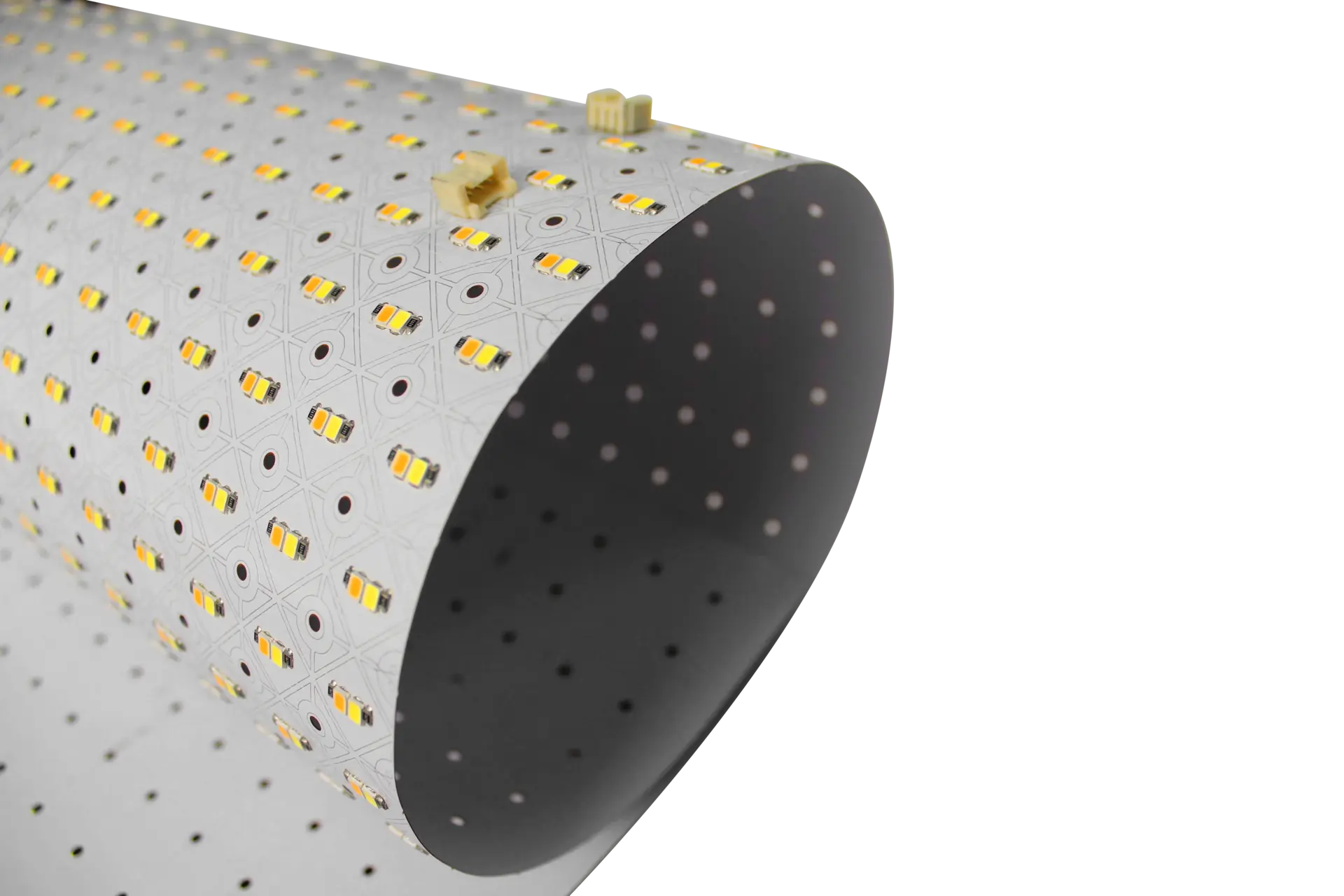

Cutting, Connecting & Mounting LED Sheets

- Cutting: follow pre-marked lines with scissors or knife.

- Connecting: use snap-on connectors for quick setups or soldering for permanence.

- Mounting: adhesive backing, clips, or diffusers for light uniformity.

👉 See the installation guide.

Key Technical Takeaways

- Ultra-thin & customizable with flexible design.

- High efficiency: 80–140 lm/W with low energy use.

- Multiple sizes, voltages, and LED types available.

- Long lifespan of 50,000–100,000 hours.

- Suitable for signage, retail, architectural, and industrial projects.

Download the Leds Do!® LightWave Flexible LED Sheets Catalog & eBook today!

Learn about specifications, installation tips, and creative applications inside

Ready to Apply LED Sheet Technology?

Now that you understand the technical details of LED sheets, see the benefits of LED sheets in real-world applications, or explore the Premium LED flexible sheet for product specifications and ordering.

Yes. Built with robust construction and long-life LEDs, most flexible LED sheets last over 50,000 hours. They resist wear, vibration, and environmental factors when installed properly.

LED sheets deliver high lumens per watt, providing bright illumination with significantly lower power consumption than fluorescent or incandescent lighting. Many projects see energy savings of up to 70–80%.

No, LED sheets run at low heat compared to traditional bulbs or fluorescent panels. While they generate some warmth, their low-voltage design dissipates heat efficiently.

A flexible LED sheet typically includes:

- A flexible backing substrate

- Arrays of LED nodes

- Copper circuits and cut lines

- A diffusion layer for smooth lighting

- Optional adhesive backing

LED sheets use a thin, flexible substrate with evenly spaced diodes and a diffusion layer. This design distributes light evenly across the surface, preventing hotspots and shadows.