SMD LED Tapes

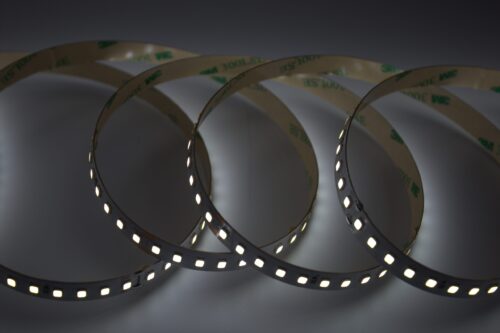

COB LED Strip Lights

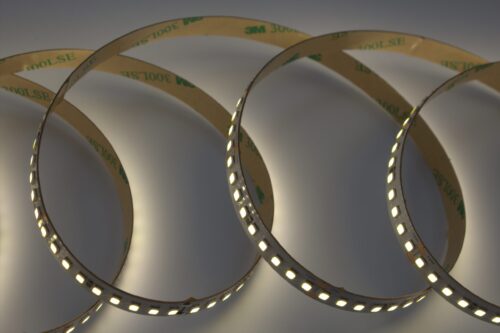

SMD LED Tapes

COB LED

Strip Lights

SMD LED Strip Lights

SMD LED Tape Light is a cutting-edge lighting solution that combines flexibility, energy efficiency, and brilliant illumination. Designed for residential and commercial use, this tape light provides seamless lighting for various applications, from accent lighting to functional task illumination.

Equipped with Surface-Mounted Device (SMD) LED technology, these tape lights deliver superior brightness and color consistency while consuming minimal energy. Available in various brightness levels, color temperatures, and even RGB options, SMD LED Strips empowers you to tailor your lighting setup to suit any space or design vision.

SMD LED Tapes FAQs

Everything You Need to Know About SMD LED Strip Lights

SMD LED strip lights have emerged as a popular option for various lighting applications, including commercial and residential settings. They are a good lighting solution for multiple places, including homes, offices, retail establishments, and even vehicle lighting, due to their adaptability, ability to generate brilliant colors, and energy efficiency.

SMD stands for “Surface-Mounted Device,” which describes how the LEDs are attached to the Strip. These LED strips are offered in various sizes, brightness levels, and colors, demonstrating their versatility. In this in-depth guide, we will discuss the advantages of using SMD LED strip lights, as well as how they are manufactured, how to cut and install them, and how to power them correctly.

A Few Advantages of Using SMD LED Strip Lights

SMD LED strip lights have several advantages compared to more conventional lighting solutions, such as incandescent and fluorescent lights. Here are some of the most important advantages:

1. The efficiency of energy use

Compared to traditional lighting solutions, LEDs consume significantly less power. Their ability to convert most electrical energy into light rather than heat makes them highly energy-efficient. This reduces electricity costs, especially for large-scale applications, and contributes to a greener environment.

2. An extended lifespan

SMD LED strip lights boast a long lifespan, typically 30,000 to 50,000 hours or even longer. This is a significant advantage over incandescent bulbs, usually lasting about 1,000 hours, and fluorescent lights, which have a lifespan of 8,000 to 10,000 hours. With SMD LED strip lights, you can enjoy long-lasting, reliable illumination without the worry of frequent replacements.

3. Capacity for Alteration and Adaptability

LED strip lights come in various lengths, colors, and brightness levels, offering endless possibilities for creative lighting solutions. Whether it’s accent lighting, under-cabinet lighting, cove lighting, or decorative lighting, the ability to bend and twist these strips allows for versatile and imaginative applications.

4. Able to be Personalized and Dimmable

Many SMD LED strips are compatible with dimmers and controllers, which means that users may alter the colors and even vary the brightness of the strips. Utilizing RGB LED strips, which allow for the customization of lighting colors, can generate a variety of moods and effects.

5. Simple assembly and setup

On the other hand, SMD LED strips come with an adhesive backing, which makes it simple to put them on virtually any surface. With little effort, they may be cut to particular lengths and linked to power supply or controllers. Additionally, they can be cut to specifications.

6. Minimum Emission of Heat

In contrast to incandescent and halogen lights, SMD LED strips produce relatively little heat, significantly reducing the risk of overheating and the potential for fire hazards. Because of this, they are a more secure choice for illumination in enclosed environments and for sensitive materials.

7. A Vast Spectrum of Possible Applications

Strip lights with SMD LEDs are utilized in a variety of applications, including the following:

- Light fixtures for the home (kitchens, bedrooms, and living areas)

- Lighting for commercial venues (such as hotels, restaurants, and retail stores)

- Lights for outside areas (such as landscaping, patios, and walks)

- Automotive illumination (including alterations to the inside and exterior of vehicles)

- Lights for events and ornamental purposes

Manufacturing Process of SMD LED Strip Lights

Understanding how SMD LED strip lights are manufactured can provide insight into their functionality and endurance.

1. Chips for LEDs

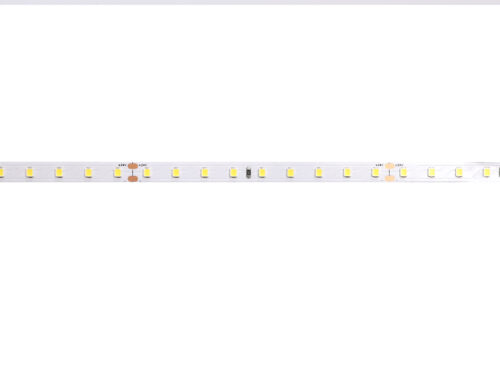

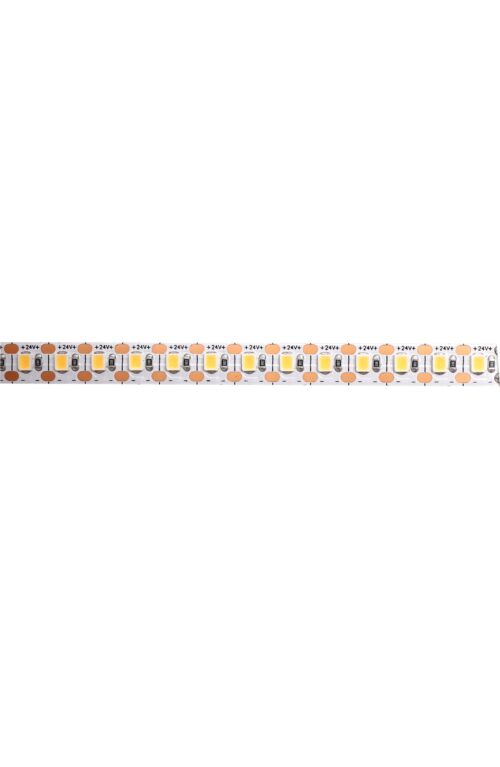

In strip lights, the LED chips utilized are SMD LEDs, which stand for surface-mounted device LEDs. These LEDs are directly put onto a flexible circuit board. Among the most prevalent varieties of SMD LED chips are the following:

- This low-brightness SMD 3528 (3.5mm x 2.8mm) is perfect for accent lighting because of its size.

- There are 5.0mm x 5.0mm SMD 5050s. – Increased in brightness, typically employed for general illumination

- 2.8mm x 3.5mm SMD 2835 component – Increased brightness and level of efficiency

- High-intensity LEDs that provide intense illumination are called SMD 5630/5730.

2. Printed Circuit Board (PCB) material that is flexible

LEDs are attached to a flexible printed circuit board (PCB), which allows the Strip to be twisted and shaped and offers electrical connectivity. Copper, typically used in producing printed circuit boards (PCBs), is known for its high conductivity and ability to dissipate heat.

3. Resistors and electronic circuitry

Each LED chip has tiny resistors attached. These resistors regulate the voltage and prevent the LEDs from burning out. Thanks to the circuit arrangement, the LEDs maintain a steady brightness level, guaranteeing their effectiveness.

4. A Protective Coating (This Is Not Required)

A silicone or epoxy coating is applied to certain LED strip lights to protect them from dust, moisture, and other physical damage. These strips are referred to as IP-rated strips, and they include:

- The IP20 standard does not include waterproofing and is intended for indoor usage.

- A splash-resistant design that is appropriate for use in bathrooms and kitchens, IP65

- Completely waterproof and suitable for use in both outdoor and aquatic settings, the IP67/IP68 standard

5. Adhesive Backing

Most LED strip lights come with an adhesive backing, usually made by 3M, significantly simplifying the installation process. This feature allows users to easily attach the Strip to walls, ceilings, furniture, and other surfaces without additional hardware. It’s a convenient and time-saving solution for DIY enthusiasts and professionals alike.

SMD LED Strip Lights: How to Cut and Install Them Installing

LED strip lights have the potential to be cut and personalized, which is one of the most significant advantages available to them. This is the correct way to carry it out:

1. Finding the Cut Lines in the Tree

These cut lines, usually indicated by a small icon of scissors, are designed into SMD LED strips to guide users where to cut. Depending on the type of Strip, they are typically spaced every three LEDs or every few centimeters. Understanding and locating these cut lines is crucial for a successful installation.

2. Making a Cut in the Strip

When cutting precisely along the set line, use sharp scissors. Any cutting that occurs outside of these lines has the potential to damage the circuit and render the Strip inoperable.

3. Reassembling All of the Cut Pieces

When you need to reattach the pieces that have been chopped, use:

Connectors for LED SMD strips (that do not require soldering)

Soldering (to create a connection that is both more secure and more lasting)

4. Mounting the Strip

To ensure that the LED strip adheres well to the

surface where you intend to mount it, you first need to clean the surface.

As you carefully press the SMD Strip onto the surface, peel off the adhesive backing.

Mounting clips provide an additional layer of security, particularly in regions exposed to weather or heavy foot traffic.

Instructions on How to Power SMD LED Strip Lights Correctly

By utilizing the appropriate power supply, LED strips can be guaranteed to last long and perform as intended.

How to Determine the Appropriate Voltage

Typically, LED strip lights are powered by either 12V or 24V DC. Before choosing a power supply, checking the Strip’s requirements is vital.

Figuring Out the Power Requirements needed to identify the appropriate source of power:

- Be sure to make sure that your LED strip has a wattage per meter.

- This should be multiplied by the whole length of the Strip itself.

- It is essential to avoid overloading the power supply, thus providing a buffer of 20-30%.

Take, for instance:

- To meet the requirements of a 5m LED strip with a rating of 12W per meter, the formula is: 12W multiplied by 5m equals 60W.

- With a buffer of twenty percent, 60W multiplied by 1.2 equals 72W

- You ought to utilize a power supply that is at least 75W.

- A Power Adapter or Driver Plug-and-play adapter is adequate for short LED strips.

- LED drivers are necessary for applications that require a lot of power.

- Dimmable drivers enable the brightness of a light source to be adjusted using a wall dimmer.

Wiring and Controllers

A controller must control RGB SMD LED strips to change colors and modes.

Connecting strips of a single hue directly to a power adapter connection is possible.

Avoid sloppy connections and use the appropriate connectors when it comes to wiring.

Final Thoughts

SMD LED strip lights are an outstanding lighting solution that offers efficiency, variety, and ease of installation. They are also a flexible lighting option. If you want to enhance your house, office, or outdoor space, LED strips offer infinite alternatives.

It is possible to generate amazing lighting effects while simultaneously maximizing their longevity, provided you grasp how they are manufactured, how to cut and install them, and how to connect them to the appropriate power source.

When properly installed, LED strip lights can completely transform any area by providing dazzling illumination that may be customized. They continue to be a popular option in contemporary lighting design, whether used for task, ambient, or decorative lighting.